Page 1 of 1

Built Gigatron with IC sockets

Posted: 31 Jan 2020, 06:43

by STodd

I have successfully built a Gigatron and I chose to use IC sockets. See attached pics.

Why use sockets? It allowed me to assemble the board and then test the sockets for power and shorts before inserting the ICs. Also, prevented too much heat being used when soldering and if an IC was faulty I could easily replace it.

I'm glad to say the Gigatron powered up and worked first time.

If you want to use sockets then here are a couple of tips to consider:

1) I used a jig to hold the board when soldering.

2) To help soldering each socket,I first used a tiny amount of glue to hold each socket in place and then soldered when the glue was set. I applied the glue to the ends of the socket with a small screwdriver.

Stephen.

Re: Built Gigatron with IC sockets

Posted: 31 Jan 2020, 13:21

by Marco

Very nice!

Maybe a bit overcautious, but whatever works for you is fine. And in the end the satisfaction of having a Gigatron build by yourself working on first try is all that matters.

Gigatron build with IC sockets works!

Posted: 02 Feb 2020, 15:36

by ECL

It is good to know that a socketed Gigatron works

without any modification.

This makes the workstation more hackable and one can plug in ECL gates with a few further modifications. Great work for posterity. Also allows for easier oscilloscoping, chip-tuning and such. That to my mind is well worth the extra money, complexity and (negligible I believe) extra potential for failure.

Re: Built Gigatron with IC sockets

Posted: 03 Feb 2020, 01:20

by monsonite

Hi ECL,

I built mine up entirely using sockets too.

Rather than glue, I would tack the socket in place by soldering two diagonally opposing pins.

Unfortunately I had just one badly soldered joint - so on first power up, operation was intermittent - but with full visual inspection - easily solved.

The board has been repopulated with fast RAM and 74F series TTL - so that it runs at 12.5MHz. I believe Marcel has one of his prototypes running at 15MHz with 74F logic.

Well done - a very rewarding project,

Ken

Re: Built Gigatron with IC sockets

Posted: 03 Feb 2020, 13:08

by ECL

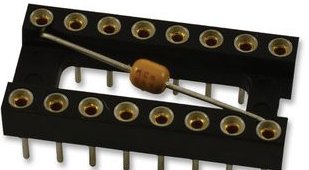

wow! 4 € for a single 16 pin socket

https://uk.farnell.com/multicomp/spc155 ... pd-mi-alte

https://uk.farnell.com/multicomp/spc155 ... pd-mi-alte

- 14-Pin Sockets - 2 Pieces

16-Pin Sockets - 25 Pieces

20-Pin Sockets - 9 Pieces

- sokk.jpg (13.03 KiB) Viewed 9332 times

they sell 7 lousy pins 1 row at 3+ € ! WTF? must be that Farnell U.K. was hit hard by BrExit now...

or 80 €cents at

https://www.mouser.de/ProductDetail/Mil ... 2BY1ipw%3D

https://ie.rs-online.com/web/p/dil-sockets/0813137/ 16 pin 50 cent

alike

socketed chip tuning with

ECL :

10125 converter

Re: Built Gigatron with IC sockets

Posted: 03 Feb 2020, 21:44

by at67

Even though I agree that price is extremely excessive, too be a little more fair it's a high quality socket with a high quality decoupling Capacitor already connected in place.

These types of sockets can save you time and money in PCB design/layout, circuit testing and offer increased operational longevity; especially for designs for high profile prototypes.

Imagine having built a prototype of the next big thing and demonstrating it in front of investors and/or potential clients, extra expenditure in these sorts of areas can pay off big time; not just in increased reliability and saving of prototyping time, but also probably more importantly, in the presentation of your product to your clients who you are trying to milk...err persuade.

Re: Built Gigatron with IC sockets

Posted: 06 Feb 2020, 06:24

by STodd

STodd wrote: ↑31 Jan 2020, 06:43

I have successfully built a Gigatron and I chose to use IC sockets. See attached pics.

Why use sockets? It allowed me to assemble the board and then test the sockets for power and shorts before inserting the ICs. Also, prevented too much heat being used when soldering and if an IC was faulty I could easily replace it.

I'm glad to say the Gigatron powered up and worked first time.

If you want to use sockets then here are a couple of tips to consider:

1) I used a jig to hold the board when soldering.

2) To help soldering each socket,I first used a tiny amount of glue to hold each socket in place and then soldered when the glue was set. I applied the glue to the ends of the socket with a small screwdriver.

Stephen.